Signode Industrial Group, a leading manufacturer of a broad spectrum of consumables, tools, software and equipment to optimize end-of-line packaging operations and protect product in transit, introduced a unique tray packaging solution at PACK EXPO International 2018 in October.

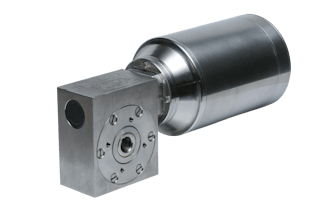

Featuring two key products — the H. BÖHL orbital stretch wrapper (pictured) and Loveshaw Little David Case Sealer SP-304 — the unique system offers users the ability to improve product integrity and increase sustainability with greater packaging efficiency. Widely popular in e-commerce applications throughout Europe, the orbital wrapper is used to secure products to trays and the case sealer ensures proper closure and sealing of the protective box.

“The breadth of our product offerings coupled with our global reach offers us a unique advantage to meet customer demands,” said Joe Albert, VP of Sales & Marketing, Global Wrapping Technology at Signode Industrial Group. “The introduction of the tray packing solution to the U.S. market is a great example of that.”

To date, several European manufacturers have successfully incorporated the equipment solution to safely package electrical components, heavy assemblies (pumps, motors, etc.) and other sensitive products. Historically, these products are packed by hand and filled with packaging material to protect products during transport. The H. BÖHL orbital stretch wrapper eliminates the need for additional expensive loose fill packaging material by providing superior load stability. Prior to the product going into the outer box, it’s first placed on a suitable tray (material type, size and weight determined by product) and placed inside the wrapper. The unique orbital design dispenses the stretch film over and under the product- securing it tightly to the tray. Once placed in the outer box the product is safely secured and rarely requires additional product protection. An intuitive design, high speeds, low material cost, maximum up-time, low noise operation, minimal setup times, and the ability to link together with an automated production line all make the Bohl a popular product load stabilizing solution.

When combined with the Loveshaw Little David Case Sealer SP-304, the tray packing system achieves even greater results. Ideal for a wide range of uniform cases and industrial environments, the reliable case sealer reduces labor costs associated with manual case sealing. An automated three flap folder, with universal bottom flap folding bars provides quick and uniform closure while automated tapping seals the box. The need to hand tape boxes closed is also eliminated. The Loveshaw Little David Case Sealer SP-304 comes equipped with interchangeable tape cartridges and top squeezer rollers. The automated CaseLocker ST tape cartridge requires no lubrication and helps alleviate twisting motions known to cause carpal tunnel syndrome. The knife guard system of the tape cartridge further ensures workers are not exposed to the blade as it is only exposed with the rollers have been depressed. The innovative design features a narrow profile “T-rail” table design and patented single mast design to allow for clear operator access. Meeting varying demands, semi-automatic and fully automatic case sealer models are also available.

Signode Industrial Group www.signode.com