When I began my career in packaging in the 1980s, productivity improvement programs were in full swing at most consumer products companies. The first, and often the most productive, target for cost savings, was in the corrugated shipping case. After all, the shipping case had three simple objectives in its short life:

- Contain the products for warehousing and transportation

- Provide the proper product identification

- Protect the product until it arrived at its final destination

As far as anyone was concerned, at the end of its useful life, that brown box could be tattered and worn, as long as the product was protected and saleable.

With the advent of the European style grocery model — one that focuses on rapid product stocking vis-a-vis “Display Ready or “Retail Ready” packaging — our little brown box has been given a promotion. That shipping box is now responsible for carrying the load of being the final marketing tool at the most critical point in the product life in sales — consumer presentation.

In addition, this transformed shipping case must be easy to open and place on the shelf, all while being visually appealing. After all, 90 percent of buying decisions are made at this point in the product distribution cycle. It truly is the big “point of sale” moment.

Unfortunately, the perception of the shipping case continues to be viewed as a necessary evil cost rather than a new opportunity to shine on the shelf. This is the last opportunity a marketer has to outperform the competitor who has decided the “good enough” approach would be, well, just “good enough.”

Yes, there are demands being made by retailers, which seem to add unnecessary costs. But is it a cost or an opportunity? Retailers are looking for a rapid pallet-to-shelf display case that is easy to stock while providing a superior shelf presence.

With all of the new graphics and material capabilities available today for display packaging, the opportunities to dominate on shelf are limitless. The use of multiple secondary packaging components provides the marketer with the ability to invest in the display tray with retail quality graphics and branding.

Utilizing E-flute or paperboard display trays maximizes the shelf appearance, further enhancing and reinforcing the product’s branding and quality appearance. A separate cover or hood using natural kraft corrugated material delivers the shipping protection for the product and the upscale display tray. The stocking clerk simply pops the cover off and places the product-filled tray on shelf, with absolutely no cutting or tearing necessary. This prevents potential product damage and provides a clean, consistent, high-quality display every time.

Several real-world examples of the conversions that are taking place right now include products that have historically been displayed on pegboard displays. The opportunity for retailers to save on the laborious effort to uncase and stock individual packages on pegs is the obvious first step in converting to shelf-ready packaging. These products include packaged cheese from sliced flow packs, to pouches of shredded cheese. This trend continues with bagged candies in stand-up pouches, as well as vertical form-fill-sealed bags.

Both of these examples have resulted in these producers moving towards more versatile shipping cases. Branded items tend to focus on two-part packages, which afford the ability to use a paperboard or e-flute display tray that accurately represents the same color and branding of the primary packaging. Other generic or private label-branded items utilize a mottled white corrugated with flexo-printed branding. All other standard products continue to be packaged in kraft corrugated shipping cases. And all of these packaging opportunities require flexibility.

From a manufacturing perspective, end-of-line secondary packaging equipment must also shoulder the burden of maintaining the flexibility to run both multi-component, shelf-ready packaging, as well as standard shipping cases for channels that do not require the point-of-purchase packaging. Having the manufacturing flexibility to run multiple case formats prevents future retailer demands from obsoleting existing equipment.

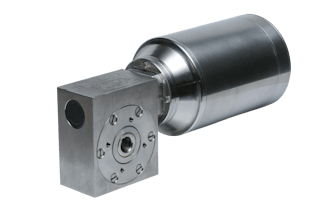

One example of this type of flexible system is the compact SOMIC 424 Mechatronic case packaging system. These types of advanced case packing systems prevent the manufacturer from being locked into one format or the other. Additionally, future retailer-specific ready designs of display trays can be added as new formats when the need arises. This becomes a competitive advantage for the producer.

Considering the amount invested into the development of retail packaged food products — the marketing, the primary packaging and the production — isn’t that last presentation to the consumer at the store level worth the final follow through? The brown box today is truly being transformed from a necessary utilitarian shipping vehicle to a significant marketing tool.

While the U.S. market is still in its infancy with retail-ready packaging, the trend toward more shelf-ready packaging is a reality. With European grocery chains such as Lidl and Aldi making significant inroads in the United States, the pressure to deliver will continue. Those producers who are prepared with flexible, end-of-line packaging systems will have a distinct advantage over their competitors who remain chained to that little brown box.

Peter Fox is Senior Vice President of Sales for Somic America Inc.