Asset maintenance managers – whether in a factory, utility or public facility — are often forced to fill multiple roles, from supervising repairs and preventive maintenance to inventorying assets and projecting their lifespans. As digitalization sweeps through industries, balancing the multiple pressures of the job can be difficult. Digital concepts rely heavily on equipment upgrades like adding sensors and Internet of Things (IoT) connectivity, pulling decision-makers in multiple directions. Analyzing capital needs and prioritizing capital investment planning can be a time-consuming burden for teams which are already stretched thin. Fortunately, technology can help streamline processes, providing the insights needed to make well-informed decisions about asset investments.

Defining the Problem

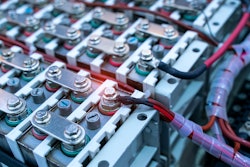

Asset management plays a critical role in the digital revolution. Network connectivity, machine learning, IoT, and Artificial Intelligence are just a few of the innovative technologies which are transforming industries. Although these technologies are largely software-driven, they also rely on equipment and machinery updates like embedding sensors, adding robotic arms, self-directed movements along tracks, automating routing, or signaling starts/stops. These machinery upgrades all require capital.

What is the Better Way?

Rather than looking at only the investment element of the equation, asset managers will be more holistic in their recommendations if they can view the big picture, from Facility Condition Assessment (FCA) to Remaining Useful Life (RUL) and Estimated Replacement Cost. The recent as-serviced history as well as costs of asset maintenance and any service contracts or warranties on the assets must also be considered.

In most enterprises, cost of unexpected downtime associated with upgrade-vs-replace decisions must be a factor, too. The ultimate question must be, “what investment options will provide the most expedient resolution, the highest level of reliability, and the least amount of disruption to operations?” The other big issue at stake: cashflow. Not only should the capital needed for the investment be considered, but the impact on personnel and any interruption to fulfilling customer needs should be considered as well. It is a complex equation.

An advanced Enterprise Asset Management solution paired with robust analytics will provide that type of broad perspective. It all starts with conducting an asset assessment. While this may take some investment of time up front, the rewards will pay off.

How to Get Started

Some information for each existing asset must be collected, if not already captured. In addition to the obvious areas, such as location of the asset, age and condition, any regulations and compliance issues should also be considered. The most important data to capture will be around the critical nature of the asset or the “value” to the organization, and that means more than replacement costs.

Managers should also note for each asset whether the technology is considered “modern” or if it has become outdated and lagging woefully behind current industry standards. Noting that the asset “works well” will not tell the complete story if the asset is also 20% slower and 30% less accurate than later versions on the market. In some industries where competitive positioning is critical, such distinctions can make or break the company’s ability to retain market share and meet the market’s changing expectations.

Applying Predictive Analytics

Once the basics are entered, it opens up the ability to monitor each asset and track performance issues which will contribute to sound financial planning. Managers can search the system for assets which need preventive maintenance and ensure the necessary parts and resources are available, while also estimating those costs.

The most significant value, though, will come from the power of predictive analytics. Today, innovative Business Intelligence (BI) solutions can contain powerful predictive capabilities, using algorithms and data science to identify patterns in data points and project next likely outcomes. Users can explore “what if” scenarios and obtain forecasts of likely costs and likely demands.

This glimpse of future investment needs can be juxtaposed against projected cash cycles also taking into account forecasts for customer demand. Managers can then prioritize major investments when funds will be available and plan for stop-gap, bare-minimum fixes during lean periods.

Managers should also be able to identify some time-sensitive critical issues which are high priority and demand an immediate response, including ones which may incur costly fines. Managers should be alert to such issues as: ADA accessibility, building code compliance, OSHA or EPA mandates, or workforce or public safety issues. Any asset which severely interrupts sales or customer satisfaction must be considered a critical one.

Applying What is Learned

The reporting generated by the EAM solution paired with advanced analytics will allow asset managers to consolidate needs across departments or business units and negotiate for possible economies of scale or bulk purchasing. By seeing the long-term investment strategy, the purchasing agents may also be able to contract better rates or plan for annual contracts.

If necessary downtime is going to be needed for any major capital investments and installation of equipment, sales and operations can be informed so they can plan accordingly. They may need to allow for longer lead-times or adjust as-available capacity or shift demands to other departments, branches, or machinery. A view into the future asset plans will help the entire enterprise prepare.

Concluding Thoughts

Just as assets today often must stretch their value and work above and beyond the basic expectations, asset maintenance staffs and their software tools must also try to “do more with less” and get extra value out of their existing solutions. That can mean using the EAM solution to also gain short and long-term capital investment insights. With the view into future demands and future capital available, asset managers can make well-informed recommendations. Top priorities and critical needs can be considered along with potential gains and benefits. Smart investments will yield success.

Kevin Price is Infor’s Technical Product Evangelist & Product Strategist.