Daniel Bévort

Daniel Bévort Enterprise tech disruption is coming to the engineered-to-order (ETO) manufacturing industry. There are four major characteristics that precede disruption and they are all present for all project-driven industries, including ETO. This article identifies those signs and discusses how you can prepare your company to meet this disruption head on rather than it barrel over you. As an example, we will look at what one optomechanical manufacturer is doing with Project Business Automation (PBA) to transform its business and take control of its future.

To begin, why do we see disruption coming to ETO and all project-driven industries?

No. 1 - Poor Customer Experience

Research shows that most projects end up over budget or behind schedule. More than just poor results, the whole process of running projects is a poor experience for the project owner as well.

Most project owners are left in the dark as to the real status of their projects until something goes drastically wrong. This is because the project vendors simply don’t have this information at their fingertips to give to the customer. This puts strain on the relationship between the customer and contractor, eroding the trust between them.

With results like these, there is vast room for improvement, setting the stage for something new to come along that offers drastically better outcomes and an improved customer experience.

No. 2 - Stagnant Performance

To make matters worse, this poor customer experience has been the status quo for decades, and it is not getting any better (see fig. 1). It is one thing to have a problem for a year or two and then see things steadily improve. But what we see from ETO manufacturing and all project-based companies is the same results for the last 20 years.

Fig.1 - PMI Pulse of the Profession 2016

Fig.1 - PMI Pulse of the Profession 2016No. 3 - Rising Customer Expectations

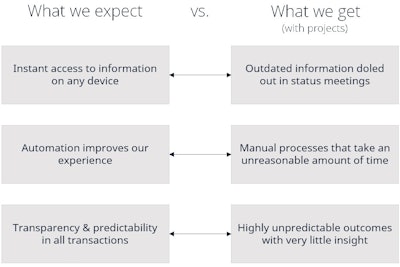

This poor and stagnant customer experience contrasts greatly compared to our experiences in every other part of our lives and in other industries.

In most other industries we see powerful technology that automates processes and generates massive new efficiencies. We see real-time data at our fingertips through our phones and tablets. We see increased transparency in business transactions. But look how this contrasts with projects in the figure below.

This difference in expectations and actual experience cannot last. Even as B2B clients, we expect real-time interactions with our vendors, but project-driven ETO firms simply can’t provide that.

No. 4 - Lack of Innovation & Outdated Tech

Up until now, enterprise technology has improved the customer experience in every other business sector except the project-driven industries such ETO manufacturing.

If we look at other industries, such as retail, distribution or high-volume manufacturing, they regularly deploy and depend on completely integrated systems based on their core business. Everything is designed to automate and support their central business model.

For example, retailers’ have POS systems and ERPs that integrate completely and predictively with their supply chain, automating the entire flow of products from the manufacturer to the shelf. That is why stock-outs occur less frequently now, why you can order online and pickup in the store, and why Amazon can deliver anything you want in two days and you know exactly where the package is the whole time.

ETO manufacturing firms simply cannot operate this way. They don’t have the right operating methodology and systems to support their project-based business models. Most still operate in silos with applications that don’t talk to each other, making it impossible to generate the same kind of access to reliable real-time information.

Take Control or Wait & See

With disruption on the horizon, the question is do you try to take control and lead your company through it or take the wait and see approach?

Leaders have the vision to get out in front of change and drive it for the betterment of the company. If you don’t take control proactively, then you are reacting to whatever the market brings to bear. Rather than waiting and becoming the victim of circumstance, the better course is to dictate what those circumstances are.

What Do You Need?

Assuming you want to lead your company through this transformation, what do you need to make it happen?

Research in project-driven industries points to three essential capabilities that companies need to develop to improve project outcomes and meet the rising expectations of customers.

- Robust Project Governance

Lack of proper project governance is a leading cause of project failures, stemming from a lack of standardized processes and performance metrics. Companies need to institute a standardized governance program with dependable metrics that demonstrate control.

- Real-time Insight

Research shows that most projects don’t fail due to big, black swan events. They fail one little issue at a time that all compound into a major problem. So, finding and fixing issues early on with real-time insight is key to improving outcomes.

- Instant Collaboration

Many project failures stem from poor communication and collaboration between workers and stakeholders. Companies need to provide mechanisms to collaborate with information in real-time, both internally and externally with the customer, enabling better communications so all parties are aligned and trust is established.

These three capabilities take the chaos out of projects and instill a sense of predictability and control back in the process, reducing real and perceived risk.

How Do You Get It?

Now the question is, how do you acquire those capabilities?

Form a methodology and systems standpoint, ETO companies need to put projects at the center and think holistically about running a project business. They cannot continue to operate in silos, employing fundamentally disconnected processes and disparate systems.

When we look at each of these capabilities, we see how to get there:

- Robust project governance is achieved by standardizing and systemizing processes across departments and functions. This makes standard, verifiable performance metrics possible.

- Real-time insight is achieved by centralizing information and data into one source of truth in real time. This means everyone operates from the same foundation and there is no delay in access to accurate data.

- Instant collaboration is achieved through standardization and through the automation of unnecessarily manual processes to eliminate error, bias and delay. This ensures every stakeholder is aligned always.

Project Business Automation in ETO Manufacturing

Qioptiq is an example of a leading company that applied this holistic approach to its ETO project business.

Like most companies in their industry, Qioptiq had no centralized view into its project portfolio. Everything was in silos and run through individual programs. There was no holistic status of all the programs in real time, which caused widespread inefficiencies across the company.

So, they first developed a vision to fully integrate their programs, operations and financials. Then they went looking for a way to systemize this vision. Unfortunately, these types of solutions were not widely available to project-driven companies historically, which is why they were operating in silos. But things are beginning to change.

In their search, Qioptiq discovered a new approach with PBA. PBA provided that unifying platform that they were seeking, helping to standardize and systemize workflows and consolidate data.

Now the company is basing its operating decisions on real-time data. All employees are working from the same set of information. This type of insight and control is unprecedented in their project-driven market and gives them a major competitive advantage.

Conclusion

In summary, we can see that the project-driven manufacturing industry is poised for disruption. We see a long history of poor outcomes and customer experience coupled with rising customer expectations. The fact that methods and approaches used in other industries have not been deployed widely yet in the ETO project industry makes the disruption even more likely.

Leaders looking to take control of their company’s future should focus on attaining better project governance along with real-time insight and collaboration. The only way to get these things is by thinking holistically about your project business. Look for ways to bring everything together, so all the parts of the business are synchronized and working seamlessly together.

I know it may sound like wishful thinking, but it is possible with the right approach and the right systems to codify and enforce this methodology. Those who do adapt quicker will drive this disruption and enjoy a significant and longer-lasting competitive advantage over those who wait and see.

Daniel Bévort is Founder & CEO of ADEACA.