Industrial manufacturing and plant operations’ professionals all have a common need to find a solution for managing surplus assets so they can focus on their many other responsibilities. Whether that consists of idle assets no longer contributing to daily operations or an entire plant closure due to consolidation of operations that needs to have all assets inventoried, valued, and redeployed or sold; successfully managing surplus assets is an important component of a healthy supply chain. Research suggests that nearly $150 billion worth of underutilized or surplus assets currently exist, and that’s a lot of potential value on the table for businesses challenged to find cost reductions or enhance cash flow and streamline operational processes.

Reduce Costs and Enhance Cash Flow through Asset Recovery

In a recent survey conducted with nearly 200 investment recovery professionals, 81% reported that the management of surplus assets is a strategic part of their business and 28% stated that recovery and costs are the top factor to success in their role. Oftentimes, the cost of keeping capital assets on the financial books is a significant motivator to selling assets; but the method by which they are sold is critical to maximizing value.

Marketing assets to a larger pool of buyers in a bidding environment is key to realizing full value. In a similar survey of over 1,500 buyers of surplus, 30% stated they look for surplus through online marketplaces. Other methods include direct through manufacturer, online fixed price, private treaty sales, and live auctions, meaning that multiple sales channels are required to reach surplus buyers. Buyers also stated that they expect a high quality of customer service supporting their surplus purchases. Since it’s a better investment of an enterprise to put their marketing, customer service, and sales infrastructure into serving their core business; the easiest way to target and serve these surplus buyers is by engaging a trusted provider with established online marketplaces, customer service, and a dedicated base of buyers to effectively sell assets.

Streamline the Reverse Supply Chain

Most leading companies have invested millions in their forward supply chain, ensuring that all aspects – from logistics to fulfillment to shipping and transport – are aligned with best practices. However, the reverse supply chain often lacks the same focus, but can carry great risk. Consider the following situations:

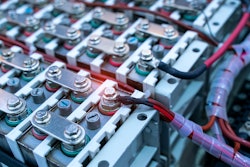

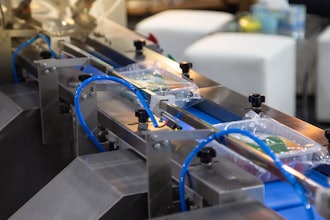

- A factory is being closed due to restructuring and specialized assembly equipment needs to be valued and sold.

- Idle technology assets are sold with personal identifiable data accidentally stored on the item.

- Surplus assets are managed through paper-based systems within the company; each time an employee moves to another department or leaves the company, historical records are lost.

In each of these scenarios, there are proven solutions that can lead to efficiencies like those implemented on the forward supply chain. This includes:

- Internal Redeployment Program: A web-based asset management system which allows users from across the globe to manage, track, and redeploy surplus enables companies to fully utilize the value of their existing assets. In addition to providing a uniform, user-friendly process, it takes the guesswork out of what to do with surplus. If there is not a department within the company that requires the asset within an allotted number of days, then the asset can automatically be moved to an online marketplace where it can be sold and return working capital to the company.

- Leveraging Best Practices from a Trusted Partner: One of the most innovative companies in the world understood that its expertise was not in managing its reverse supply chain and turned to a vendor to create a process that would align with its internal systems and procedures. Selling specialized assets is difficult for a manufacturer and can test the bandwidth of operational employees forced to market an asset, find a buyer, and then manage the removal, shipping, and collection of payment, not to mention, ensure that it’s compliant with company and state and federal regulations with services such as data wiping and export controls. Through a vendor partnership, the company can provide its goals for the project or surplus program and the vendor can design a solution to deliver that result, provide metrics and reporting that can be easily communicated to management making operations look like a hero to the business.

Conclusion

The sale of surplus is a critical part of the strategy for a successful business. Rather than going it alone and navigating the secondary markets without a map, implementing an internal redeployment program to better utilize the full lifecycle of assets and engaging a provider who has a dedicated base of buyers, comprehensive services, online marketplaces, and a proven track record, will fuel success. Managing and selling surplus assets can add value and enhance innovation with a winning strategy.

Gardner Dudley is an executive leader for the Capital Assets Group at Liquidity Services, a global solution provider in the reverse supply chain with the world’s largest marketplace for business surplus. He can be reached at [email protected] and more information about the company is at www.liquidityservices.com.